HACCP for Bars and Restaurants: A Practical Beginner Guide

- 9 hours ago

- 5 min read

HACCP (Hazard Analysis and Critical Control Point) is a practical way to prevent food safety problems before they reach a guest. In a cocktail bar, “food” includes ice, garnishes, juices, syrups, dairy, eggs, and any house-made prep that is stored, portioned, or served.

If you want a ready-to-use logging system that makes HACCP record-keeping fast and consistent, the HACCP Record-keeping Toolkit is available in the Operations Toolkits for Bars area on The Double Strainer.

HACCP in plain English

HACCP is a system for identifying what could make food unsafe, controlling it at the steps that matter most, and documenting those controls. It shifts safety from “good intentions” to repeatable checks that still work during rushes, staff turnover, and inspections.

HACCP sits on top of basic hygiene

Most safety is built through prerequisite programs: the daily foundations that make HACCP possible. In bars, that typically includes personal hygiene rules, cleaning and sanitation routines, supplier and receiving checks, pest prevention, and equipment maintenance (especially fridges and ice machines). If these basics are weak, HACCP becomes paperwork.

The 7 principles in bar reality

Identify hazards.

Decide where control is essential (critical control points).

Set limits for those points.

Check them on a schedule.

Define what happens after a failure.

Confirm the system works.

Keep records.

Build a simple HACCP plan for a bar

1) Set scope

Start with the highest-risk items: fresh juice, dairy, egg products, ready-to-eat garnishes, and ice handling. Expand later.

2) Create a flow for each prep or station

Example: receive ingredients → store → prep → hold → serve → discard → clean.

3) Identify hazards at each step

Microbiological: harmful bacteria, viruses, mould, spoilage.

Chemical: sanitizer residue, cleaning chemical misuse, allergen cross-contact.

Physical: glass chips, fruit stickers, plastic, metal fragments.

4) Choose realistic control points

In bars, CCPs often appear where time and temperature matter or where contamination is likely. Typical candidates:

Cold holding for high-risk preps.

Ice storage and handling hygiene (ice is consumed).

Sanitizer concentration when chemical sanitation is relied on for food-contact surfaces.

Keep CCPs few. A control point is only useful if the team can monitor it in real time and correct it immediately.

Short advanced sidebar: CCPs vs prerequisites

A common mistake is turning everything into a CCP. If the risk is reliably controlled by routine good practice (cleaning schedules, handwashing rules, equipment maintenance), keep it as a prerequisite. Use CCPs for the steps where losing control creates a genuine safety risk and you can define a clear pass or fail limit.

5) Set limits you can actually run

Avoid limits like “keep cold” or “clean often.” Write limits that are measurable or clearly observable, and aligned with your local legal requirements and manufacturer instructions.

Examples of workable limit formats:

“Cold holding stays at or below the venue’s legal limit.”

“Label includes made-on date and discard date.”

“Sanitizer concentration stays within the manufacturer’s stated range for food-contact surfaces.”

“Ice scoop stored off the ice, in a clean holder, never left inside the bin.”

6) Monitoring that fits service

Use triggers instead of random checks.

Opening: fridges, ice bin condition, sanitizer setup, labels.

Mid-shift: high-risk preps still within hold windows, tools stored correctly.

Closing: discards done, cleaning completed, issues logged.

7) Corrective actions that protect guests and the business

Corrective actions should be pre-written so the team does not improvise.

Examples:

If cold holding is out of limits: move at-risk items to a verified cold unit, place product on hold, discard anything that cannot be proven safe within policy, document the cause and fix.

If sanitizer is out of range: stop using it on food-contact surfaces, remake it correctly, re-sanitize, document.

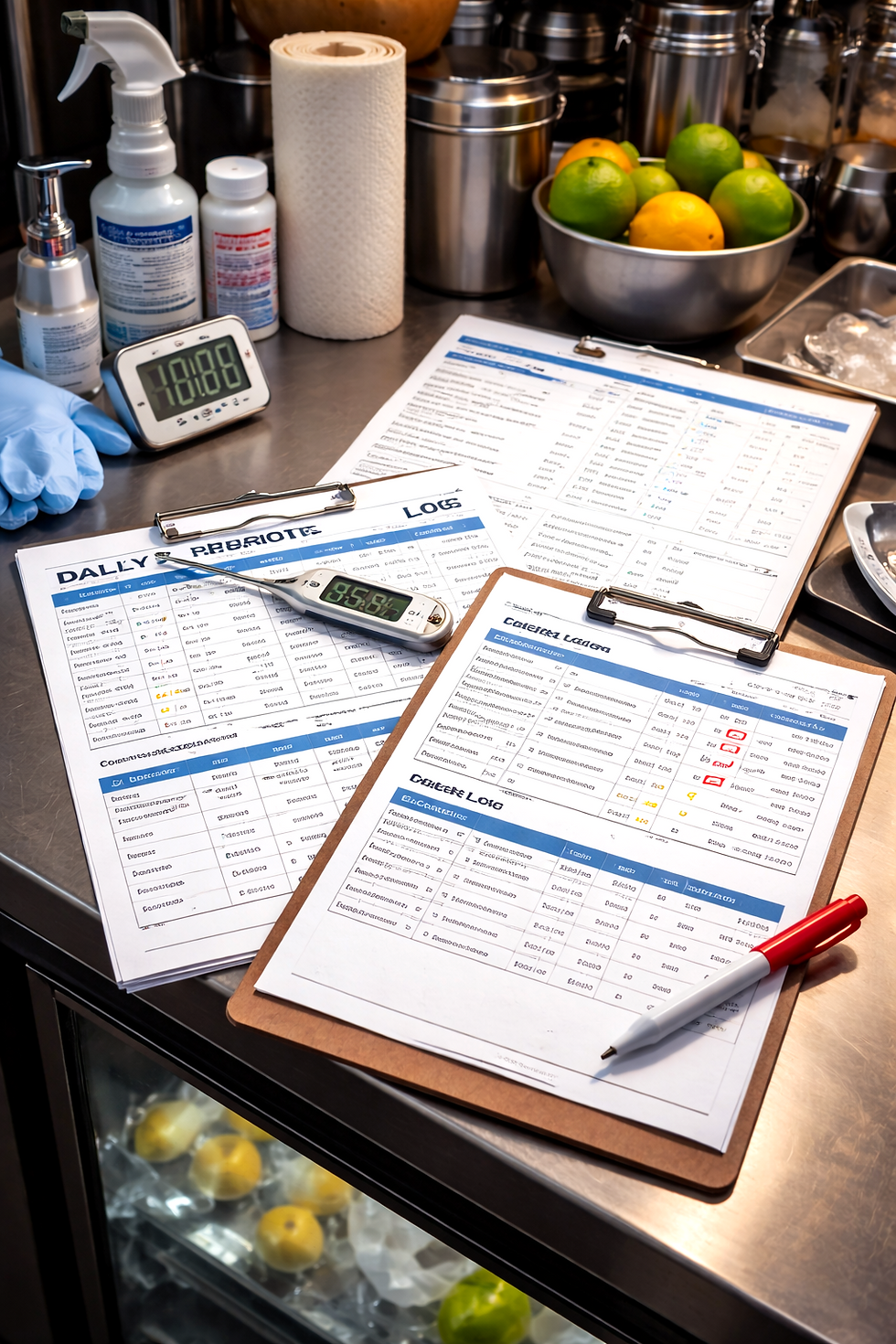

Record-keeping that survives an inspection

Most bars do checks, then fail to prove them consistently. The goal is not “more paperwork.” It is a small set of records that are quick to complete, easy to review, and tied to real actions.

If you want bar-ready logs, labels, and verification checklists without building everything from scratch, the HACCP Record-keeping Toolkit can be purchased from the Operations Toolkits for Bars area on The Double Strainer.

Minimum viable HACCP records for a bar

Receiving checks: Supplier, date, condition, rejects, and temperatures where relevant.

Cold storage checks: Fridge and freezer checks at opening (plus additional checks if your operation requires them), with actions recorded for deviations.

Prep and labeling logs: Batch name, made-on time, discard time, initials, and key allergen notes where applicable.

Cleaning and sanitation logs: What was cleaned, when, and by whom. Include sanitizer checks if chemical sanitation is part of the control.

Corrective action log: What happened, product affected, immediate action, root cause, prevention.

Make records work in real life

Keep logs at the station, not in an office.

Use checkboxes where possible.

Review completed logs daily. Unreviewed logs become a habit, not a control.

Maintain and calibrate measurement tools (thermometers, test strips) so recorded values are meaningful.

Common mistakes and how to fix them

Too many CCPs

Fix: keep CCPs limited to essential, measurable steps.

Limits that cannot be monitored

Fix: rewrite limits into measurable or observable terms.

“Everyone is responsible”

Fix: assign each check to a role and attach it to opening or closing duties.

Logs filled out later

Fix: tie checks to a trigger and store the form at point of use.

Chemical and allergen risks ignored

Fix: include chemical handling and allergen cross-contact controls in prerequisites, then train and verify them.

FAQ

What does HACCP stand for?

Hazard Analysis and Critical Control Point.

Is HACCP only for factories?

No. The principles are used across food service, including restaurants and bars, adapted to the size and complexity of the operation.

Do bars really need HACCP?

Many regulators require HACCP-based procedures or equivalent food safety management. Even when not strictly required, the approach reduces incidents and makes training easier.

What is the difference between a prerequisite and a CCP?

Prerequisites are baseline hygiene and operational controls. A CCP is a step where control is essential to prevent or eliminate a hazard or reduce it to an acceptable level.

How often should checks happen?

Often enough to control risk, but not so often they fail in reality. Most bars succeed with opening, mid-shift, and closing triggers for key controls.

What records do inspectors usually ask for?

Commonly: evidence of temperature control, cleaning and sanitation routines, and documented corrective actions. Exact expectations vary by jurisdiction.

Does HACCP apply to drinks?

Yes, whenever ingredients or processes can create hazards, including ice, garnishes, dairy, eggs, and house-made preps.

Glossary

CCP (Critical Control Point): A step where control is essential for safety.

Critical limit: A pass or fail value or condition for a CCP.

Corrective action: Steps taken when a limit is not met.

Deviation: A failure to meet a critical limit.

Hazard analysis: Identifying and evaluating hazards in your process.

Monitoring: Scheduled checks to confirm control.

Prerequisite programs: Baseline hygiene and operational controls that support HACCP.

Sanitizer concentration: The strength of a sanitizing solution used on surfaces.

Verification: Activities that confirm the plan works (calibration, audits, record review).

HACCP is not about creating a binder. It is about running safer prep and proving it with simple, consistent records. Start small, keep the checks realistic, and review logs like they matter.

To implement HACCP record-keeping quickly with bar-ready logs and checklists, use the HACCP Record-keeping Toolkit available in the Operations Toolkits for Bars area on The Double Strainer.

Explore more practical builds and operational techniques in the Bar Business section.

Want a weekly plain-English summary plus extra tips and tools? Join the Newsletter.

Written by: Riccardo Grechi | Head Mixologist, Bar Consultant & Trainer