Bar SOP: How Do You Write Standard Operating Procedures Staff Actually Follow?

- 18 hours ago

- 7 min read

A bar can look busy and still be out of control. Drinks vary by bartender, prep gets skipped under pressure, cleaning happens “when there’s time,” and new hires learn by copying whoever is loudest on the shift. Bar SOPs solve that problem by turning expectations into repeatable steps that can be trained, checked, and improved.

A bar SOP is not paperwork for its own sake. It is a safety net for consistency, speed, and guest experience, especially when the team changes, the venue gets slammed, or leadership is off the floor.

If you want to build SOPs faster and keep formatting consistent across the whole bar, the SOP Builder Toolkit from The Double Strainer is the most direct shortcut to go from “messy notes” to a clean SOP library.

Beginner quick guide (copy and use)

Keep each SOP to one task, one page, one outcome.

Write steps in the exact order they happen in real service.

Define the standard: what “done” looks like, not just what to do.

Add verification: who checks, how often, and where it is recorded.

Assign one owner per SOP (responsible for updates).

Train with a demo, then have staff perform it once with feedback.

Audit lightly but consistently (spot checks beat rare deep audits).

Update SOPs after menu changes, equipment changes, or repeated mistakes.

What a bar SOP is, in plain words

A bar SOP (Standard Operating Procedure) is a written, repeatable method for completing a specific task. In a bar, that task might be setting up a station, batching a pre-mix, closing the cash drawer, cleaning a draft line, or handling an intoxicated guest.

A good SOP does three things:

It removes guesswork.

It protects standards across different staff and shifts.

It creates a fair reference point for training and accountability.

The difference between a checklist and a real SOP

Many bars start with checklists. That is useful, but it is not enough on its own.

A checklist answers: “Did this happen?” An SOP answers: “How is it done, to what standard, and how is it verified?”

Example:

Checklist item: “Clean the espresso machine.”

SOP standard: “Backflush with approved cleaner, rinse cycle completed, group head wiped, drip tray washed, exterior sanitized, then logged by initials.”

The key point is measurability. If two people can interpret it differently, it will be executed differently.

A bar-ready SOP format that stays readable

A simple format keeps SOPs usable during real service. For each SOP, include:

1) Title and ID: Use a short, consistent naming style: “OPEN-01: Bar Opening Setup” or “PREP-05: Citrus Labeling.”

2) Scope: Where it applies. Example: main bar only, service bar only, events only.

3) Role owner: Who executes it, and who verifies it.

4) Frequency and timing: Every shift, opening, closing, weekly, or “as needed.”

5) Steps (numbered): Short verbs, one action per line.

6) Standard (definition of done): The non-negotiable outcome.

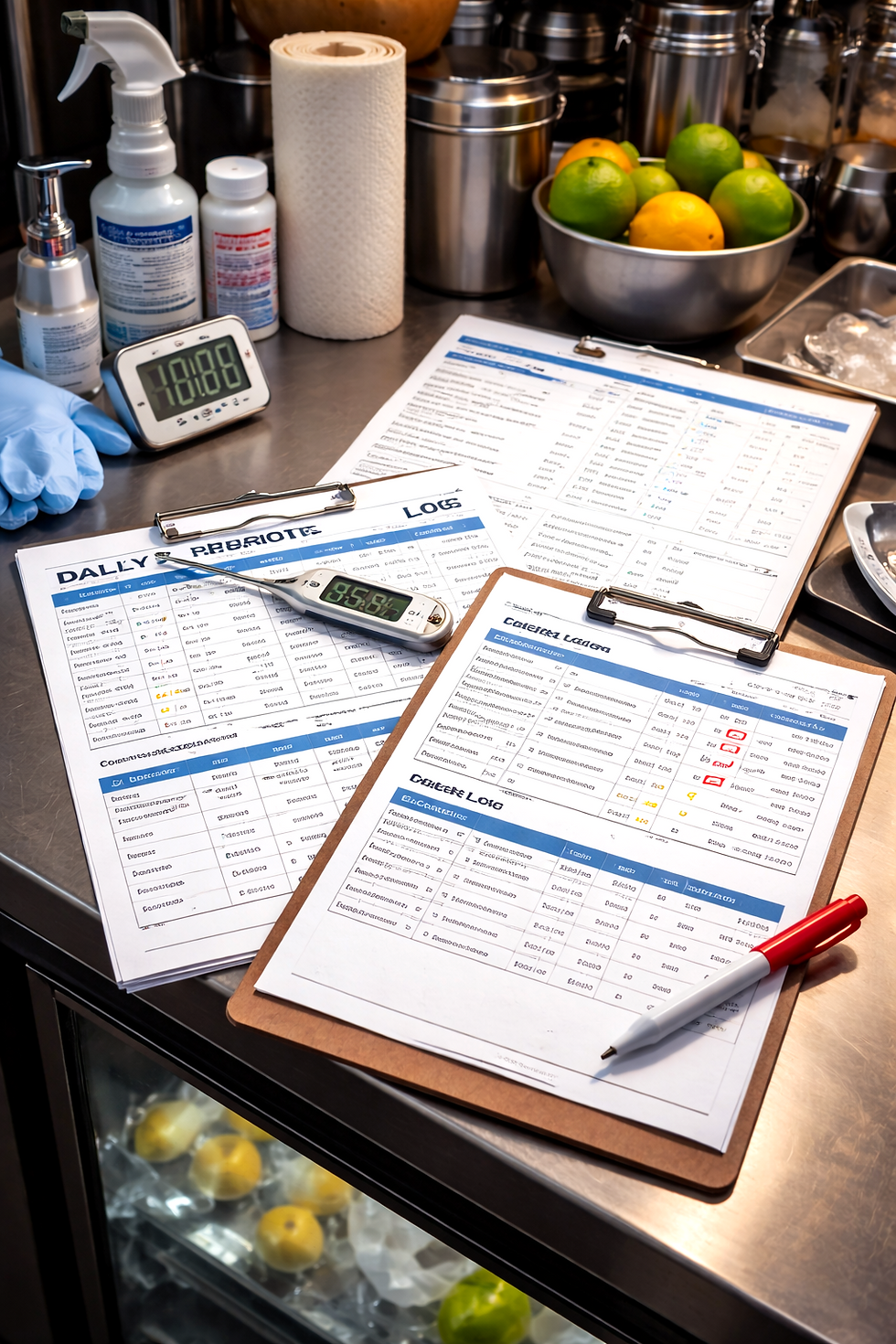

7) Verification: How the bar knows it was done: sign-off, photo, logbook entry, POS report, waste sheet, temperature log, or manager spot check.

That structure scales. It works for recipe execution, cleaning, maintenance, and management routines.

What to include in a bar SOP library

Instead of one long manual nobody reads, build a library of short SOPs grouped by module. A practical bar structure:

Service and drink build standards

House recipes and standard builds

Glassware and garnish standards

Ice standards by drink style

Stir and shake time cues, strain rules, dilution targets (expressed simply)

Service bar ticket flow and priorities

Station setup and shift routines

Opening setup by station

Restock rules and par levels for each station

Shift handover notes: what must be communicated

Closing breakdown, storage rules, lock-up

Prep, batching, and labeling

Prep lists by daypart and day of week

Label format and dating rules

Allergen notes where relevant

Cross-contamination prevention and storage separation

Batch yield checks and waste recording

Inventory and waste control

Receiving and storage rules

FIFO (first in, first out) for perishables

Spill, comp, and breakage logging

Stock counts: how, when, and who signs off

Cash handling and POS

Opening float check

Comp and void rules

Cash-out and tip-out steps

End-of-night close and safe drop

Safety, compliance, and incident handling

Alcohol service rules vary by country and license type. SOPs should reflect local requirements and venue policy, but the structure stays the same:

ID check steps and escalation

Cut-off procedure and documentation

Incident log: what gets written down, where it lives, who is notified

Emergency basics: injuries, spills, broken glass, power failure

How to write SOPs that staff actually follow

A common failure is writing SOPs like a textbook. Bar SOPs succeed when they read like the shift.

Use “service language,” not management language

Prefer: “Sanitize tins and strainers, then air-dry.”Avoid: “Ensure sanitation protocols are followed.”

Write for exceptions, not only perfect days

If a bar only documents the ideal scenario, staff will improvise during chaos. Add a short “If X happens” line when needed:

If glass breaks in the ice well, stop service on that ice, discard it, sanitize the well, and log it.

Reduce friction

If the SOP requires hunting for tools, it will fail. Put the tool location into the SOP once, then keep it consistent:

“Blue labels are in the left prep drawer.”

Make standards visible

Where possible, SOPs should produce visible outcomes:

A labeled batch bottle.

A completed log entry.

A reset station photo in a shared folder.

Implementation: the part most bars skip

Writing SOPs is not the finish line. Implementation is training, verification, and repetition.

Step 1: Pick a “critical 10” first

Start with the SOPs that stop the biggest problems:

Opening setup

Closing breakdown

Citrus and juice labeling

House cocktail builds

Waste logging

Cash-out and tip-out

Deep cleaning rotation

Incident documentation

Inventory count procedure

Shift handover

Once those are stable, expand.

Step 2: Assign owners and set a review rhythm

Each SOP needs one owner. Ownership is not about ego, it is about clarity. Add a simple review rhythm:

Monthly light review for service SOPs

Quarterly review for cleaning and maintenance

Immediate review after menu changes or recurring mistakes

Step 3: Train with a demo and a “do it once” sign-off

A fast training loop beats long meetings:

Demonstrate once.

Staff performs once.

Correct on the spot.

Sign off when the standard is met.

Step 4: Audit with spot checks

Audits do not have to feel punitive. Keep them small:

Two SOP spot checks per week.

Five minutes each.

Track repeat failures and fix the cause (unclear steps, missing tools, unrealistic timing).

If you want a clean format and a faster build process, the SOP Builder Toolkit from The Double Strainer is designed to help create consistent SOPs, checklists, and training-ready pages without reinventing the structure every time.

Troubleshooting: common SOP problems and fixes

Problem: SOPs are ignored

Cause: unclear standards or no verification.

Fix: add a measurable standard and a sign-off point.

Problem: SOPs are too long

Cause: one SOP tries to cover an entire department.

Fix: split into smaller SOPs by task and timing.

Problem: “Everyone does it their way”

Cause: the SOP does not match reality, or tools are inconsistent.

Fix: rewrite based on observed service flow and standardize the station layout.

Problem: Training does not stick

Cause: training is talk-based, not action-based.

Fix: demo plus perform plus sign-off. Add short refreshers during pre-shift.

Problem: SOPs become outdated

Cause: no owner and no review cadence.

Fix: assign owners, add review dates, update after changes.

Problem: SOPs create resentment

Cause: SOPs are used as punishment instead of support.

Fix: position SOPs as fairness and consistency. Apply them equally, including leadership.

Advanced sidebar (keep it short): document control in a bar

Treat SOPs like controlled documents, even if the system is simple. Use version numbers, a single “source of truth” location, and a change log line that states what changed and why. When a standard changes, retrain the affected roles and remove old printed pages immediately. The fastest way to break SOP compliance is to let multiple versions float around the venue.

If you want to go deeper

Explore more bar systems, training, and management frameworks in the Business section on The Double Strainer.

Before closing, one last step: if SOP work is the goal, make it easy to execute. The fastest path is using a structured builder instead of writing from scratch, available via Menu Costing & Engineering Toolkits.

FAQ

What does SOP stand for in a bar?

SOP stands for Standard Operating Procedure: a repeatable method for completing a task to a defined standard.

How many SOPs does a bar need?

Start with 10 to 15 high-impact SOPs, then expand as the system stabilizes.

Should SOPs be printed or digital?

Both can work. Digital is easier to update; printed is easier to use in the moment. Many bars use digital as the master and print role-specific pages.

Who should write bar SOPs?

Leadership should own the standards, but staff input matters. The best SOPs reflect real workflow.

How often should SOPs be reviewed?

Review service-critical SOPs monthly, and update immediately after menu or equipment changes.

What is the best way to train SOPs fast?

Demonstrate once, have staff perform once, then sign off when the standard is met.

Are SOPs only for large bars?

No. Smaller teams benefit just as much because coverage gaps hurt more when one person is missing.

Glossary

SOP (Standard Operating Procedure): documented method for completing a task consistently.

Standard (definition of done): the measurable outcome that counts as completed correctly.

Verification: the check that proves completion (sign-off, log, photo, report).

Owner: the person responsible for keeping an SOP current and realistic.

FIFO: first in, first out rotation for perishables and stock.

Par level: target on-hand quantity needed to operate smoothly.

Mise en place: station setup and prepped items needed for service.

Audit: a quick check to confirm standards are met.

Incident log: documentation of service issues, injuries, refusals, or removals.

Handover: shift-to-shift communication of key operational details.

Related reading

SOP Toolkit purchase path: Menu Costing & Engineering Toolkits

Recipe exploration: Cocktails section

Ingredients learning: Ingredients section

Want practical, technique-first operations guidance delivered when new articles go live? Join the Newsletter.

Written by: Riccardo Grechi | Head Mixologist, Bar Consultant & Trainer